Material: Steel.

- For fixing a hub on a shaft. - QPQ coated: High corrosion resistance, improved fatigue strength, primarily food safe (further information see below). - For medium torques. - Self-centering. - Slight axial offset possible during assembly.

Fit, Surface: Due to the special design of the BAR clamping set even rough fits can be bridged with excellent self centering capacity. Shaft and hub up to Quality h8/H8. Surface finish for shaft and hub Rz < 12 µm.

QPQ Surface Properties: Very good corrosion resistance, better than hard chrome or chem. nickel. Corrosion resistance in the salt spray test SS CASS in accordance with DIN 50021. Layer thickness of 10 - 25 µm possible. For medium operational demands we recommend a layer thickness of 15 µm at a 90 minute treatment. Only very small changes in dimensions (only 5 µm), as the surface modification is achieved through diffusion and not application. Surface hardness same as clamping set material = 350 HV. Improved wear resistance, no fretting corrosion, no cold shut. Increased endurance strength, sometimes up to 100% higher. Is completely safe to use with food as long as there is no contact with any acidic substances with a pH-value of = 4.

služby: online CAD katalog

Dodávané 3D modely, obrázky a technické výkresy jsou vyrobeny s velikou péčí. Přesto je vyloučena odpovědnost za přesnost a správnost těchto údajů.

viz také:

součást skupin produktů:

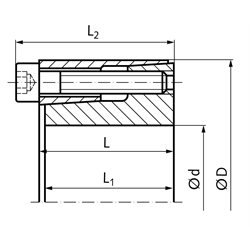

| číslo výrobku | d [mm] |

D [mm] |

L [mm] |

L1 [mm] |

L2 [mm] |

přenášený točivý moment T [Nm] |

přenášená axiální síla Fax [kN] |

povrchový tlak na hřídeli P W [N/mm2] |

povrchový tlak na náboji PN [N/mm2] |

šrouby velikost (DIN 912, 12.9) | utahovací moment TA [Nm] |

šrouby počet | hmotnost [kg] |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 61571600 | CAD | 16 | 32 | 17 | 16,5 | 21,0 | 86 | 10 | 158 | 79 | M4 x 16 | 4,9 | 4 | 0,067 |