These servo gearboxes are characterised by high torsional rigidity and very low torsional backlash. This enables high acceleration and precise positioning accuracy in your application.

General data: Universal heavy-duty worm gear boxes. 4 sizes, centre distance 40, 50, 63 and 80 mm. On request with keyway in the hollow shaft

and centre distance 100mm available. Permissible ambient temperature -20°C to +40°C.

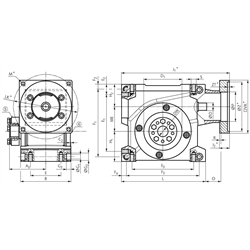

Housing: High quality aluminium die-casting, all sides machined and with mounting holes on 5 sides.

Gearing: 6 ratios from 4,0 to 39,0 : 1. Worm shaft hardened and ground, worm wheel made of high-performance bronze, Gear backlash <6 arcmin. On request, at extra cost and depending on size, the backlash can get decreased by the factory <2 arcmin.

Efficiency factor: The efficiency factors stated in the selection tables are guideline values for properly run-in and lubricated gearboxes at operating temperature with nominal load and driving worm shaft.

Self-locking: The servo worm gear unit isn‘t self-locking.

Bearing Systems: Generously dimensioned ball-bearings for continuous modes. Input side with fixed and loose bearing, output side bearing in eccentric cover. On request available with tapered roller bearing for dynamic operation and high external force.

Lubrication: On delivery with food-grad lubricant NSF-H1 filled (FDA approved). On request, the gearbox can be filled with other lubricants at the factory. Under normal operating conditions, no maintenance is required.

Ventilation: No ventilation screw necessary. The venting is effected by hermetic pressure compensation (Membran), The membran is independent from the mounting position and in the housing integrated.

Delivery: 2 products have to be ordered:

- the servo worm gear unit with shrink disc on the output side 5 or 6.

- the motor adaptation with coupling, flange and fixing screws.

1) permittable output torque T2 zul. under consideration of thermal limits.

2) maximum output torque T2 max.without consideration of the permissible torque of the coupling and the output side shrink disk.

3) with a service life of 12.000 hours and continuous operating S1 at 1.500 min-1.

services: online CAD catalog operating manual

The supplied 3D models, pictures and technical drawings are made with reasonable care. Nevertheless liability is excluded for the accuracy and correctness of this data.

found in parts groups:

| part number | Baugröße | Übersetzung i = | n1 max. [min-1] |

T1 zul. [Nm] |

T2a max. [Nm] |

T2 zul. 1) 3) [Nm] |

T2 max. 2) [Nm] |

TKW [Nm] |

c [Nm/arcmin] |

η3) [%] |

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 42104100 | CAD | 40 | 4,0 : 1 | 8000 | 13,9 | 59 | 53 | 179 | 37 | 5 | 95 |