Material: Up to D1 = 28 mm hubs made of brass, chromated and passivated. From D1 = 41,4 mm aluminium alloy with iridite NCP finish.Torque ring made of black polyacetal. These unique, zero backlash, general purpose couplings provide electrical insulation. They are designed for the lower torque range and offer generous angular and radial misalignment compensation. Their axial stiffness is unique and they can anchor unrestricted shafts or perform light push/pull duties. Applications: Ideal for stepper motors due to the damping properties of plastic torque rings. Positioning drives, position encoders and incremental or absolute encoders, pumps etc. Temperature range: -20ºC to +60ºC. 1) At lower speeds the couplings can compensate up to +/-1 mm radial and 10º angular displacement. 2) Operating factors: see coupling HB.

services: online CAD catalog further information

The supplied 3D models, pictures and technical drawings are made with reasonable care. Nevertheless liability is excluded for the accuracy and correctness of this data.

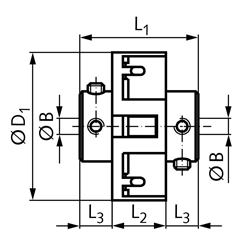

| part number | Torque max. [Nm] |

Stat. Breaking Torque [Nm] |

Bore +0,03-0 | L1 [mm] |

L2 [mm] |

L3 [mm] |

D1 [mm] |

Max. Displacement at 3000 rpm [°] |

Max. Displacement at 3000 rpm [radial [mm]] |

Torsional Rigidity [Nm/rad] |

Gewicht [g] |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60100200 | CAD | 0,3 | 0,9 | 2 | 14,2 | 5,1 | 4,6 | 18,0 | 2 | 0,20 | 25 | 7 |

| 60100300 | CAD | 0,3 | 0,9 | 3 | 14,2 | 5,1 | 4,6 | 18,0 | 2 | 0,20 | 25 | 7 |

| 60100400 | CAD | 0,3 | 0,9 | 4 | 14,2 | 5,1 | 4,6 | 18,0 | 2 | 0,20 | 25 | 7 |

| 60100700 | CAD | 1,7 | 5,0 | 3 | 19,1 | 6,9 | 6,1 | 28,0 | 2 | 0,20 | 92 | 16 |

| 60100800 | CAD | 1,7 | 5,0 | 4 | 19,1 | 6,9 | 6,1 | 28,0 | 2 | 0,20 | 92 | 16 |

| 60100900 | CAD | 1,7 | 5,0 | 6 | 19,1 | 6,9 | 6,1 | 28,0 | 2 | 0,20 | 92 | 16 |

| 60101000 | CAD | 1,7 | 5,0 | 8 | 19,1 | 6,9 | 6,1 | 28,0 | 2 | 0,20 | 92 | 16 |

| 60101300 | CAD | 3,5 | 10,5 | 6 | 28,4 | 11,2 | 8,6 | 41,4 | 2 | 0,25 | 299 | 30 |

| 60101400 | CAD | 3,5 | 10,5 | 8 | 28,4 | 11,2 | 8,6 | 41,4 | 2 | 0,25 | 299 | 30 |

| 60101500 | CAD | 3,5 | 10,5 | 10 | 28,4 | 11,2 | 8,6 | 41,4 | 2 | 0,25 | 299 | 30 |

| 60101800 | CAD | 3,5 | 10,5 | 12 | 28,4 | 11,2 | 8,6 | 41,4 | 2 | 0,25 | 299 | 30 |