Material: Metal parts: Steel, zinc-plated. Elastomer: Natural rubber, 55° Shore hardness.

Rubber-Metal buffers are simple, reasonably priced standard components used for elastic mounting. When shearing load occurs their load-bearing capacity is considerably lower than with pressure load. This has to be considered when horizontal mass forces or belt traction occur. The grade of rubber used has perfect physical properties. Temperature resistant up to 80°C. For a linear resilience characteristic the Spring Load C means, for any operating point, the constant relation of load F [N] to jounce travel f [mm]. C = F/f [N/mm]. In the technical data, these constants are stated as CD for pure pressure load and as CS for pure shear load. * F perm. is the permissible static permanent load, which may be overlaid by a dynamic, alternating load. With shearing load please take care that no tension load in the rubber occurs at all during mounting. To achieve a sufficient fatigue strength provide some compressive prestressing. The stated permissible loads are only approximate, guideline values for the static load for "medium" rubber hardness. With particularly high, dynamic, alternating loads or high frequencies, the load figures have to be accordingly reduced.

services: online CAD catalog

The supplied 3D models, pictures and technical drawings are made with reasonable care. Nevertheless liability is excluded for the accuracy and correctness of this data.

see also:

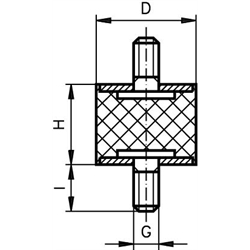

| part number | D [mm] |

H [mm] |

G [mm] |

I [mm] |

Druck Federrate CD mittel [N/mm] |

Zul. Druckbelastung F zul.* [N] |

Schub Federrate CS mittel [N/mm] |

Zul. Schubbelastung F zul.* [N] |

Gewicht [g] |

|

|---|---|---|---|---|---|---|---|---|---|---|

| 68528000 | CAD | 8 | 8 | M3 | 6 | 30 | 35 | 9 | 10 | 1 |

| 68528100 | CAD | 10 | 10 | M4 | 10 | 44 | 43 | 9 | 15 | 3,2 |

| 68528300 | CAD | 10 | 15 | M4 | 10 | 29 | 43 | 5 | 15 | 3,9 |

| 68528600 | CAD | 15 | 7 | M4 | 10 | 174 | 95 | 29 | 35 | 5,8 |

| 68528700 | CAD | 15 | 8 | M4 | 10 | 160 | 95 | 27 | 35 | 6 |

| 68528800 | CAD | 15 | 10 | M4 | 10 | 124 | 95 | 24 | 35 | 6,4 |

| 68528900 | CAD | 15 | 20 | M4 | 13 | 54 | 95 | 10 | 35 | 7 |

| 68529000 | CAD | 15 | 15 | M4 | 10 | 61 | 95 | 13 | 35 | 7,8 |

| 68530100 | CAD | 20 | 8 | M6 | 18 | 307 | 170 | 36 | 60 | 15 |

| 68530200 | CAD | 20 | 10 | M6 | 18 | 150 | 170 | 40 | 60 | 15 |

| 68530400 | CAD | 20 | 15 | M6 | 18 | 130 | 170 | 24 | 60 | 20 |

| 68530420 | CAD | 20 | 20 | M6 | 18 | 100 | 170 | 20 | 60 | 19 |

| 68530425 | CAD | 20 | 25 | M6 | 18 | 70 | 170 | 13 | 60 | 20 |

| 68530500 | CAD | 25 | 20 | M6 | 18 | 85 | 170 | 17 | 60 | 30 |

| 68530700 | CAD | 25 | 10 | M6 | 18 | 750 | 280 | 74 | 95 | 20 |

| 68530715 | CAD | 25 | 15 | M6 | 18 | 140 | 280 | 25 | 95 | 27,5 |

| 68530725 | CAD | 25 | 25 | M6 | 18 | 600 | 280 | 37 | 95 | 32 |

| 68530730 | CAD | 25 | 30 | M6 | 18 | 71 | 280 | 17 | 95 | 40 |

| 68530800 | CAD | 30 | 15 | M8 | 20 | 525 | 400 | 58 | 140 | 37 |

| 68530900 | CAD | 30 | 20 | M8 | 20 | 204 | 400 | 40 | 140 | 56 |

| 68530925 | CAD | 30 | 25 | M8 | 20 | 180 | 400 | 33 | 140 | 58 |

| 68531100 | CAD | 30 | 30 | M8 | 20 | 108 | 400 | 25 | 140 | 65 |

| 68531110 | CAD | 30 | 40 | M8 | 20 | 85 | 400 | 18 | 140 | 64 |

| 68531120 | CAD | 40 | 15 | M8 | 20 | 380 | 650 | 90 | 250 | 79 |

| 68531123 | CAD | 40 | 25 | M8 | 23 | 270 | 650 | 60 | 250 | 84 |

| 68531128 | CAD | 40 | 25 | M10 | 28 | 270 | 650 | 60 | 250 | 90 |

| 68531200 | CAD | 40 | 30 | M8 | 23 | 213 | 650 | 43 | 250 | 102 |

| 68531230 | CAD | 40 | 30 | M10 | 28 | 213 | 650 | 40 | 250 | 105 |

| 68531300 | CAD | 40 | 40 | M8 | 23 | 140 | 650 | 22 | 250 | 115 |

| 68531400 | CAD | 50 | 25 | M10 | 28 | 583 | 1000 | 84 | 400 | 155 |

| 68531500 | CAD | 50 | 20 | M10 | 28 | 857 | 1000 | 110 | 400 | 141 |

| 68531600 | CAD | 50 | 30 | M10 | 28 | 375 | 1000 | 66 | 400 | 163 |

| 68531700 | CAD | 50 | 40 | M10 | 28 | 260 | 1000 | 53 | 400 | 178 |

| 68531750 | CAD | 50 | 50 | M10 | 28 | 200 | 1000 | 39 | 400 | 199 |

| 68531760 | CAD | 60 | 40 | M10 | 28 | 390 | 1500 | 60 | 550 | 231 |

| 68531770 | CAD | 70 | 45 | M10 | 28 | 450 | 1800 | 70 | 750 | 401 |

| 68531800 | CAD | 75 | 25 | M12 | 37 | 2710 | 2300 | 211 | 850 | 369 |

| 68531840 | CAD | 75 | 40 | M12 | 37 | 734 | 2300 | 117 | 850 | 420 |

| 68531900 | CAD | 75 | 50 | M12 | 37 | 506 | 2300 | 91 | 850 | 483 |

| 68532000 | CAD | 75 | 55 | M12 | 37 | 417 | 2300 | 78 | 850 | 514 |

| 68532100 | CAD | 100 | 40 | M16 | 42 | 1970 | 4200 | 257 | 1600 | 715 |

| 68532150 | CAD | 100 | 50 | M16 | 42 | 900 | 4200 | 160 | 1600 | 800 |

| 68532155 | CAD | 100 | 55 | M16 | 42 | 892 | 4200 | 145 | 1600 | 845 |

| 68532200 | CAD | 100 | 30 | M16 | 42 | 3800 | 4200 | 310 | 1600 | 630 |

| 68532300 | CAD | 100 | 60 | M16 | 42 | 809 | 4200 | 136 | 1600 | 890 |

| 68532400 | CAD | 50 | 45 | M10 | 33 | 215 | 1000 | 43 | 400 | 208 |

| 68532500 | CAD | 100 | 75 | M16 | 42 | 750 | 4200 | 110 | 1600 | 1295 |