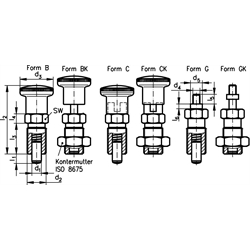

Material: Steel, black oxide finish, plunger pin hardened. Knob: Plastic Thermoplast (polyamide) black, matt finish, cannot be disassembled. Indexing plungers 817 offer the following advantages: - small outer dimensions - most of the release mechanism (version C/CK) is covered - defined thread length by an undercut at the end of the thread (version G/GK).

Version B/BK: With knob, without notched catch, this version is used where, on releasing the knob, the plunger pin should be returned to its initial position by the spring force.

Version C/CK: With knob, is used if the plunger pin has to remain in retracted position. To achieve this, the knob is rotated by 90 degrees after being retracted. A notched catch stops the locked-in knob from returning to its initial position accidentally or due to vibration.

Version G/GK: With threaded plunger end, for applications where a special knob to customer's request is required or where the plunger pin is not shifted manually.

services: online CAD catalog

The supplied 3D models, pictures and technical drawings are made with reasonable care. Nevertheless liability is excluded for the accuracy and correctness of this data.

| part number | Form | d1 -0,02/-0,04 [mm] |

l1 min. [mm] |

d2 [mm] |

d3 ca. [mm] |

d4 [mm] |

d5 [mm] |

l2 [mm] |

l3 [mm] |

l4 [mm] |

l5 Anfang [mm] |

l6 Ende [mm] |

sw [mm] |

Federdruck Anfang ca. [N] |

Federdruck Ende ca. [N] |

Gewicht [g] |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 66668400 | CAD | B | 4 | 4 | M8x1 | 16 | - | - | 35 | 16 | 5 | - | - | 10 | 4,0 | 12,0 | 11,0 |

| 66668500 | CAD | B | 5 | 5 | M10x1 | 19 | - | - | 40 | 18 | 6 | - | - | 12 | 5,0 | 15,0 | 18,0 |

| 66668600 | CAD | B | 6 | 6 | M12x1,5 | 23 | - | - | 48 | 22 | 6 | - | - | 14 | 6,0 | 19,0 | 29,0 |

| 66668700 | CAD | B | 8 | 8 | M16x1,5 | 28 | - | - | 58 | 26 | 8 | - | - | 17 | 8,5 | 26,0 | 63,0 |

| 66669000 | CAD | B | 10 | 12 | M16x1,5 | 28 | - | - | 58 | 26 | 8 | - | - | 17 | 9,5 | 38,0 | 64,0 |

| 66669400 | CAD | BK | 4 | 4 | M8x1 | 16 | - | - | 35 | 16 | 5 | - | - | 10 | 4,0 | 12,0 | 13,8 |

| 66669500 | CAD | BK | 5 | 5 | M10x1 | 19 | - | - | 40 | 18 | 6 | - | - | 12 | 5,0 | 15,0 | 25,0 |

| 66669600 | CAD | BK | 6 | 6 | M12x1,5 | 23 | - | - | 48 | 22 | 6 | - | - | 14 | 6,0 | 19,0 | 39,0 |

| 66669800 | CAD | BK | 8 | 8 | M16x1,5 | 28 | - | - | 58 | 26 | 8 | - | - | 17 | 8,5 | 26,0 | 83,0 |

| 66670000 | CAD | BK | 10 | 12 | M16x1,5 | 28 | - | - | 58 | 26 | 8 | - | - | 17 | 9,5 | 38,0 | 79,8 |

| 66670400 | CAD | C | 4 | 4 | M8x1 | 16 | - | - | 35 | 16 | 5 | - | - | 10 | 4,0 | 12,0 | 13,0 |

| 66670500 | CAD | C | 5 | 5 | M10x1 | 19 | - | - | 40 | 18 | 6 | - | - | 12 | 5,0 | 15,0 | 21,0 |

| 66670600 | CAD | C | 6 | 6 | M12x1,5 | 23 | - | - | 48 | 22 | 6 | - | - | 14 | 6,0 | 19,0 | 33,0 |

| 66670800 | CAD | C | 8 | 8 | M16x1,5 | 28 | - | - | 58 | 26 | 8 | - | - | 17 | 8,5 | 26,0 | 66,5 |

| 66671000 | CAD | C | 10 | 12 | M16x1,5 | 28 | - | - | 58 | 26 | 8 | - | - | 17 | 9,5 | 38,0 | 69,6 |

| 66671400 | CAD | CK | 4 | 4 | M8x1 | 16 | - | - | 35 | 16 | 5 | - | - | 10 | 4,0 | 12,0 | 15,8 |

| 66671500 | CAD | CK | 5 | 5 | M10x1 | 19 | - | - | 40 | 18 | 6 | - | - | 12 | 5,0 | 15,0 | 28,0 |

| 66671600 | CAD | CK | 6 | 6 | M12x1,5 | 23 | - | - | 48 | 22 | 6 | - | - | 14 | 6,0 | 19,0 | 43,0 |

| 66671800 | CAD | CK | 8 | 8 | M16x1,5 | 28 | - | - | 58 | 26 | 8 | - | - | 17 | 8,5 | 26,0 | 86,5 |

| 66672000 | CAD | CK | 10 | 12 | M16x1,5 | 28 | - | - | 58 | 26 | 8 | - | - | 17 | 9,5 | 38,0 | 85,0 |

| 66673400 | CAD | G | 4 | 4 | M8x1 | - | M3 | 7 | - | 16 | 5 | 4,5 | 2,5 | 10 | 4,0 | 12,0 | 88,0 |

| 66673500 | CAD | G | 5 | 5 | M10x1 | - | M4 | 8 | - | 18 | 6 | 5,5 | 3,0 | 12 | 5,0 | 15,0 | 15,8 |

| 66673600 | CAD | G | 6 | 6 | M12x1,5 | - | M5 | 9 | - | 22 | 6 | 7,0 | 3,5 | 14 | 6,0 | 19,0 | 25,3 |

| 66673800 | CAD | G | 8 | 8 | M16x1,5 | - | M6 | 10 | - | 26 | 8 | 8,5 | 4,0 | 17 | 8,5 | 28,0 | 53,9 |

| 66674000 | CAD | G | 10 | 12 | M16x1,5 | - | M6 | 10 | - | 26 | 8 | 8,5 | 4,0 | 17 | 9,5 | 38,0 | 55,6 |

| 66674400 | CAD | GK | 4 | 4 | M8x1 | - | M3 | 7 | - | 16 | 5 | 4,5 | 2,5 | 10 | 4,0 | 12,0 | 36,8 |

| 66674500 | CAD | GK | 5 | 5 | M10x1 | - | M4 | 8 | - | 18 | 6 | 5,5 | 3,0 | 12 | 5,0 | 15,0 | 22,8 |

| 66674600 | CAD | GK | 6 | 6 | M12x1,5 | - | M5 | 9 | - | 22 | 6 | 7,0 | 3,5 | 14 | 6,0 | 19,0 | 35,3 |

| 66674800 | CAD | GK | 8 | 8 | M16x1,5 | - | M6 | 10 | - | 26 | 8 | 8,5 | 4,0 | 17 | 8,5 | 26,0 | 73,9 |

| 66675000 | CAD | GK | 10 | 12 | M16x1,5 | - | M6 | 10 | - | 26 | 8 | 8,5 | 4,0 | 17 | 9,5 | 38,0 | 75,6 |