Material: Housing made of steel, black, powder-coated.

Tensioning pulley made of ultra-high-molecular weight polyethylene based on PE-UHMW, electrostatically dissipative.

These small, ready-to install tensioners enable noise reduction and wear reduction at belts.

• With three springs. On choice: Two tensioning force versions. At both versions, three different forces can get activated.

• With colored wear-off indicator: Green: o.k. Yellow: still o.k. Red: Tensioning force too low.

• Usable travel up to the end of the yellow range: About 32mm. Total travel about 40mm.

• Max. permissible belt speed 6m/s.

Temperature range: -20°C bis +60°C.

* Tensioning way. ** Max. recommended belt width. *** Tensioning force range.

Adjustable Tensioning Forces:

On choice, there are two versions, with low tensioning force or with high tensioning force. Both versions have three springs, which can get activated independent from each other to reach three different tensioning forces.

Version with low tensioning force:

1 spring activated: 58 - 32 N.

2 springs activated: 116 - 64 N.

3 springs activated: 174 - 96 N.

Version with high tensioning force:

1 spring activated: 132 - 60 N.

2 springs activated: 264 - 120 N.

3 springs activated: 396 - 180 N.

services: online CAD catalog operating manual

The supplied 3D models, pictures and technical drawings are made with reasonable care. Nevertheless liability is excluded for the accuracy and correctness of this data.

found in parts groups:

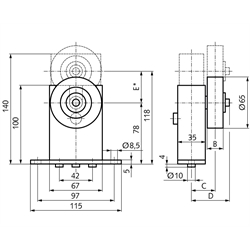

| part number | B [mm] |

C [mm] |

D [mm] |

E* [mm] |

b** [mm] |

F*** [N] |

Gewicht [kg] |

|

|---|---|---|---|---|---|---|---|---|

| 14041411 | CAD | 20 | 30 | 48 | 40 | 15 | 60 - 396 | 0,89 |