Material: Steel 11SMn30 (1.0715). Max. Operating Angle 45°. The cardan joints KE are, other than the cardan joints with needle-roller bearing, only sliding-contact bearings. Their scope of application is therefore limited to slow running drives. The respective maximum speeds depend on operating angle and load, but must never exceed 1000 rpm. The maximum torque values listed in the table are limits, which must neither be exceeded. They may only be used to their full extend with intermittent operation or at low speed. The following limit applies: The product of speed (rpm) x working angle (degrees) may not exceed the reference number 500. This means, e.g., for a working angle of 10 degrees a max. speed of 50 rpm. If, however, the maximum torque is not taken to the limit, speed and working angle can be larger. At 0.5 x max. torque applies: speed x working angle, smaller or equal 4.000. In case of doubt choose larger joint. At continuous operation the cardan joints need to be sufficiently lubricated. If no drip-feed lubrication is possible, lubricate the joints at least once a day. Another possibility is to cover the joints with a bellow, filled with a suitable lubricant.

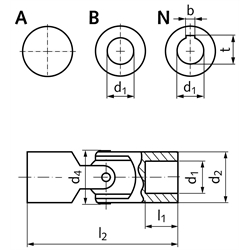

Typ A: without bores. Type B: with bores. Type N: with bores and keyways DIN 6885-1 on both sides.

služby: online CAD katalog další informace

Dodávané 3D modely, obrázky a technické výkresy jsou vyrobeny s velikou péčí. Přesto je vyloučena odpovědnost za přesnost a správnost těchto údajů.

| číslo výrobku | verze | d1H7 [mm] |

d2 [mm] |

d4 [mm] |

l1 [mm] |

l2 [mm] |

bJS9 [mm] |

t [mm] |

točivý moment max. [Nm] |

hmotnost [kg] |

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 63001000 | CAD | A | - | 10 | 10,5 | 12 | 40 | - | - | 2 | 0,020 |

| 63001300 | CAD | A | - | 13 | 14,0 | 12 | 42 | - | - | 6 | 0,035 |

| 63001600 | CAD | A | - | 16 | 17,5 | 15 | 52 | - | - | 8 | 0,067 |

| 63002000 | CAD | A | - | 20 | 21,5 | 18 | 62 | - | - | 20 | 0,138 |

| 63002500 | CAD | A | - | 25 | 26,5 | 22 | 74 | - | - | 30 | 0,230 |

| 63003200 | CAD | A | - | 32 | 33,5 | 25 | 86 | - | - | 60 | 0,440 |

| 63004000 | CAD | A | - | 40 | 42,0 | 32 | 108 | - | - | 160 | 0,880 |

| 63005000 | CAD | A | - | 50 | 52,5 | 40 | 132 | - | - | 290 | 1,710 |

| 63006300 | CAD | A | - | 63 | 64,0 | 50 | 166 | - | - | 550 | 3,070 |

| 63011000 | CAD | B | 6 | 10 | 10,5 | 12 | 40 | - | - | 2 | 0,014 |

| 63011300 | CAD | B | 8 | 13 | 14,0 | 12 | 42 | - | - | 6 | 0,024 |

| 63011300N | CAD | N | 8 | 13 | 14,0 | 12 | 42 | 2 | 9 | 6 | 0,024 |

| 63011600 | CAD | B | 10 | 16 | 17,5 | 15 | 52 | - | - | 8 | 0,047 |

| 63011600N | CAD | N | 10 | 16 | 17,5 | 15 | 52 | 3 | 11,4 | 8 | 0,047 |

| 63012000 | CAD | B | 12 | 20 | 21,5 | 18 | 62 | - | - | 20 | 0,089 |

| 63012000N | CAD | N | 12 | 20 | 21,5 | 18 | 62 | 4 | 13,8 | 20 | 0,089 |

| 63012500 | CAD | B | 16 | 25 | 26,5 | 22 | 74 | - | - | 30 | 0,160 |

| 63012500N | CAD | N | 16 | 25 | 26,5 | 22 | 74 | 5 | 18,3 | 30 | 0,16 |

| 63013200 | CAD | B | 20 | 32 | 33,5 | 25 | 86 | - | - | 60 | 0,310 |

| 63013200N | CAD | N | 20 | 32 | 33,5 | 25 | 86 | 6 | 22,8 | 60 | 0,31 |

| 63014000 | CAD | B | 25 | 40 | 42,0 | 32 | 108 | - | - | 160 | 0,625 |

| 63014000N | CAD | N | 25 | 40 | 42,0 | 32 | 108 | 8 | 28,3 | 160 | 0,63 |

| 63015000 | CAD | B | 32 | 50 | 52,5 | 40 | 132 | - | - | 290 | 1,200 |

| 63015000N | CAD | N | 32 | 50 | 52,5 | 40 | 132 | 10 | 35,3 | 290 | 1,20 |

| 63016300 | CAD | B | 40 | 63 | 64,0 | 50 | 166 | - | - | 550 | 2,400 |

| 63016300N | CAD | N | 40 | 63 | 64,0 | 50 | 166 | 12 | 43,3 | 550 | 2,40 |